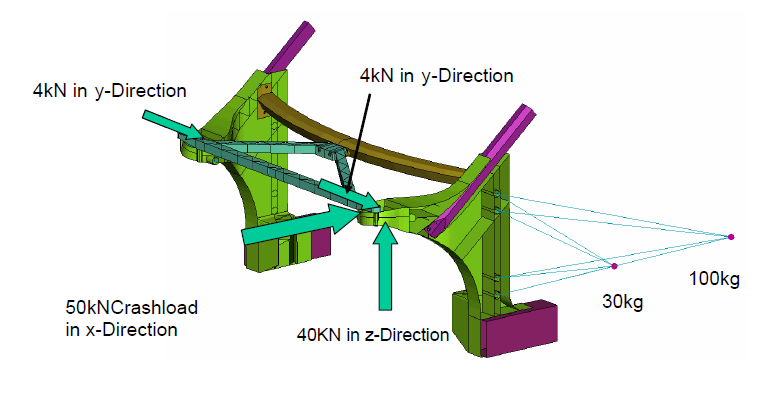

DLR and Meridian technologies (link) developed a lower middle range car Front End Carrier (FEC) with topology optimization. Methodology-wise, it is interesting that they utilised predefined forces applied to spring elements in order to obtain a realistic force distribution, instead of using rigid constraints. This way, the lack of the rest of the car body did not cause errors in the simulation. The optimized structure was translated to an injection cast magnesium structure, which integrates many functions and replaces 12 steel molded sheets. Thus the cost of the structure remains the same as steel one, while offering around %50 weight savings. It is reported that the structure is lighter than aluminium structures too, however only marginally lighter than steel-polymer hybrids which we covered before (1) , (2).

Also techniques for corrosion protection of Mg structures are briefly discussed.

Also check our previous article featuring Meridian.