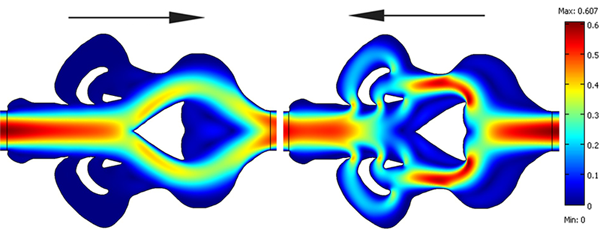

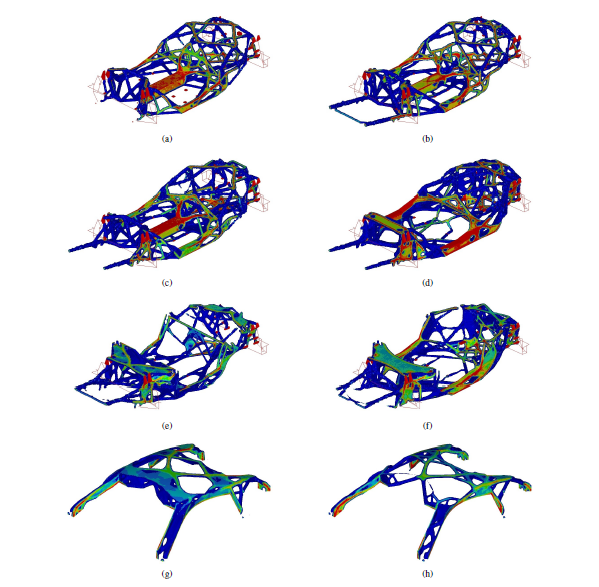

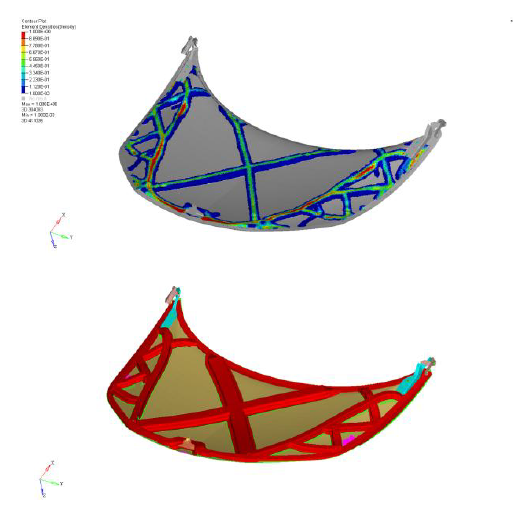

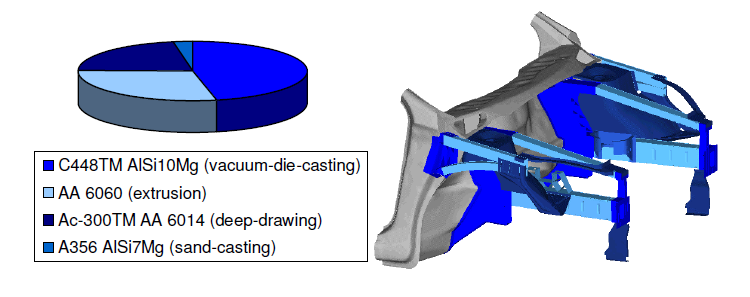

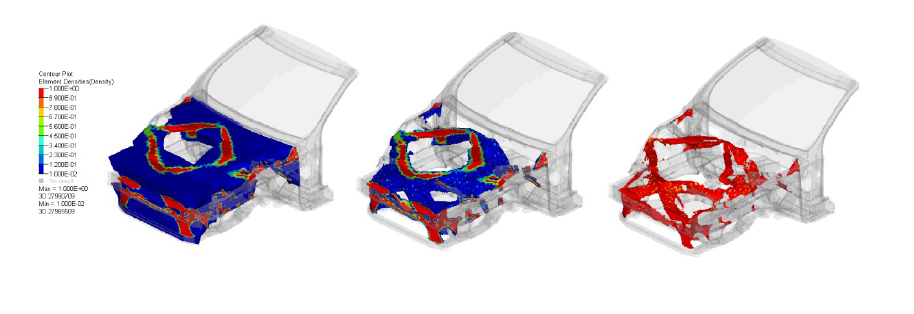

In this rather long text (seems to be a thesis) by Emil Norberg and Sebastian Lövgren of Liköpings University (link), a vehicles front structure is being optimized. We could not read it so far, however a quick skimming reveals that different parameters and meanings of different results and techniqes were discussed, which is a much needed thing in this area. Seems to be a interesting work.

Tags

2D 3-D print 3D Additive Layer Manufacturing aerospace Aesthetics Airbus aircraft ALM alternative AMG architecture article Audi automotive bayer bearing beginner bell crank billet biomimic. dendrite BLOODHOUND BMW Body in white bolt Bracket brake Brembo bridge caliper Car casting CFRP frame free hybrid interpretation machining magnesium mesh Optimization race software Topology wing-

Recent Posts